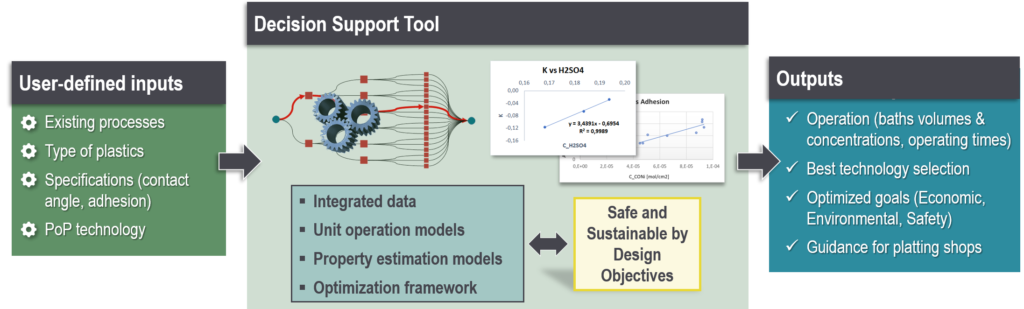

Plating on Plastics (PoP) using external electric potential is practically infeasible since most plastics are non-conductive. The current technologies utilize hexavalent chromium (carcinogenic and highly toxic) and Palladium (Critical Raw Material) revealing significant concerns for the replacement of existing technologies following the Safe- and Sustainable-by-Design principles. The FreeMe project is focused on the development of two new alternative Plating on Plastics (PoP) processes based on etching or spraying technologies to prepare the adhesion of a metal layer on plastics. Beyond experimental testing, validation and scaling up of the novel PoP technologies, there are vital questions about the optimization of operating conditions and adaptation of the new processes to existing plating shops. For this purpose, computational modelling capacities are built to simulate FreeMe technologies and are embedded in a Decision Support Tool (DST), which is oriented to guide the FreeMe stakeholders towards the adoption of new operations and technological capacities.

The modelling and knowledge background of the FreeMe DST includes new unit operation models and kinetics, property estimation models and databases, which are continuously updated with new data generated during the project. The FreeMe DST can also be used as an optimization tool to tune the design of the PoP shop ensuring optimality of economic, environmental and safety objectives.

The complete online version of the DST software will be published by the end of the project (middle of 2026).

The DST takes advantage of State of The Art (STA) modelling approaches to develop higher-order reaction kinetics for the etching and Nickel activation mechanisms. In addition, new customizable models were built based on FreeMe experimental data to fill in the gaps between existing STA modelling techniques and the new modeling challenges of emerging FreeMe technologies.

The etching technology is composed of 4 processing stages: (i) Etching of plastic surface, (ii) Activation of the surface with Nickel salts, (iii) Reduction of Ni2+ to Ni0 and (iv) Electroless platting of the activated surface. The production performance of each stage was predicted by building corresponding kinetic models. Output specifications – like the contact angle of the plastic surface or the adhesion of the metal layer – can be predicted at high accuracy by new regression models and relationships identified among operating parameters, phenomena, and properties across stages of the platting shop.

The models of each stage, the property estimation models, and complementary constraints for end-user specifications (e.g. adhesion on automotive, aerospace or home appliances compartments) were stated as an optimization problem. As a result, the DST returns the best propositions for operating conditions and equipment design that optimize selected economic, environmental and safety criteria, or even balanced optimization of all criteria. The design propositions include options for the used agents and bath concentrations, operating times and bath volumes of the etching technology offering stakeholders valuable guidance to adapt and tune the etching FreeMe technology when renovating existing infrastructures.